Grating Solver Development Company

Genetic Algorithm Thin File Design Example:

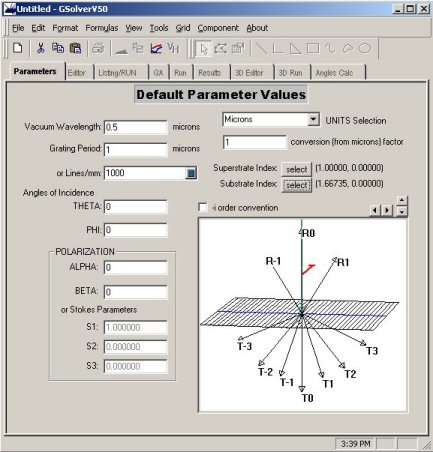

In this example the optimal AR (antireflection) coating thickness is sought for MgF2 on an Al2O3 substrate in air at normal incidence at 0.5 m wavelength.

See the User's Manual for screen shots and further details.

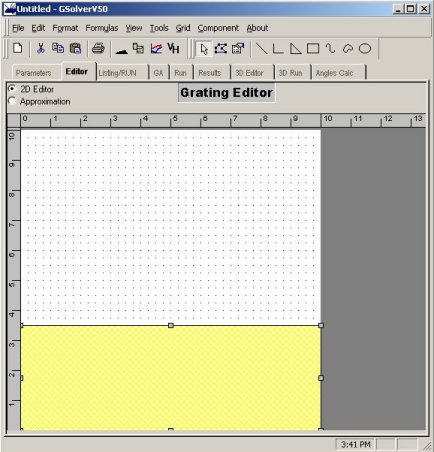

- Open a new grating editor window

- Change the wavelength to 0.5 microns on the Parameter tab

- Change the Substrate material to Table: Al2O3

- Using the Rectangle tool in the Editor tab, create a thin film coating with width of the canvas and of arbitrary thickness.

- Set the rectangle material property to Table: MgF2

- Click the Approximation button which creates the piecewise grating data structure

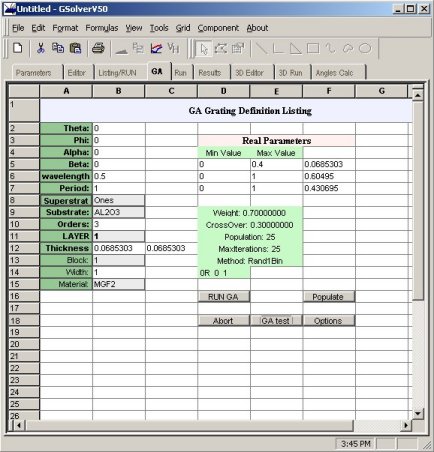

- On the GA tab click Populate

- On the GA Options dialog, click the Options button, enter the following goal 0 R 0 1 (click Add)

- This indicates that the specular reflection has 0 energy the AR condition. Click OK

- In cell B12 enter the following formula =if(F5>0&&F5<0.2,F5,0)

- Change E5 to 0.4

- Click the GA test button to exercise the parameter selection and verify that the thickness is being updated, and constrained (non-negative and <0.2)

- Click RUN GA

- The merit function (Best Energy) is updated each time a new minimum is found. The final result is updated to the listing. The result should be somewhere around 0.09

- Increasing the maximum constraint may cause the region of multiple minima to be reached. If so, multiple 'optimal' solutions may be found by executing the GA algorithm multiple times

While the GA is running, the current generation and best merit function are displayed. A merit function value of 0 indicates that an optimal solution has been found based on the goals given.

Upon completion the GA loads the values of the best parameters to the grid and creates a table of all the diffraction orders (-Orders to +Orders for T & R). This example is easily extendable to include multiple thin film layers. Simply add the materials in the Editor tab and use a separate parameter for each layer thickness.